Smart Automation Solutions for the Food and Beverage Sector

Safe, Hygienic, and Efficient: Robotics in Food & Beverage

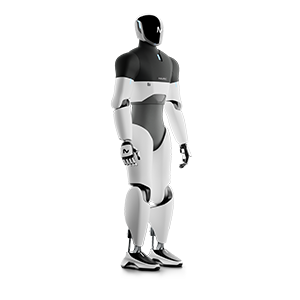

Rising consumer expectations, labor shortages and strict hygiene regulations put manufacturers under constant pressure as the food and beverage industry continues to grow. To stay competitive, they must maintain consistent quality, boost production efficiency and rapidly adapt to changing product demands. Automation is essential, but traditional industrial robots often lack the flexibility and adaptability required in today’s food production environments. Modern robotic solutions are transforming food and beverage manufacturing by enabling safe, intelligent and hygienic automation. These systems support consistent output, reduce manual strain, and help meet the industry’s strict standards for quality and compliance.

Enhance

Food Safety

Collaborative robots reduce direct human contact in critical processing steps and support strict hygiene standards.

Automate Repetitive Tasks

Repetitive tasks such as packing, palletizing and material handling can be automated with consistent speed and accuracy.

Flexible

Production

Food and beverage producers can quickly adapt to rising global demand and changing consumer preferences with automation solutions.

Consistency in filling and dosing

Robots ensure precise filling and dosing, reducing waste and ensuring product consistency.

Efficient Product Handling

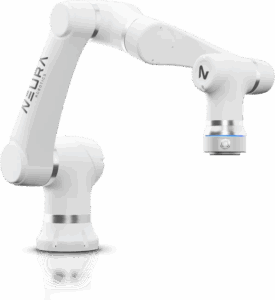

with Robotic Pick and Place

Pick and place is one of the most common applications for collaborative robots in the food and beverage industry. Cobots handle items such as baked goods, chocolate or packaged snacks with precision and care, placing them quickly and accurately into trays, packaging or containers. They reduce manual handling, improve hygiene and ensure consistent product placement, even with delicate or irregular products. They also adapt quickly to changes in product types or packaging formats.

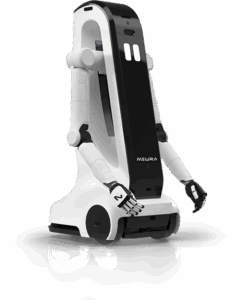

Robotic Palletizing Made Easy

for Modern Food Facilities

Palletizing and packaging tasks can be easily automated with modern robotics to increase efficiency and reduce physical strain. They pack, stack and wrap products with high precision and ensure accurate placement even in fast-paced environments. Thanks to a compact size, various robots fit into existing lines and small production spaces. Quick setup and easy format changes allow seamless adaptation to different packaging sizes and pallet patterns. This flexibility makes them ideal for high mix, end-of-line automation in modern food facilities.

Precision Filling and Quality Inspection

for Consistent Food Production

In applications like bottling, portioning sauces or distributing dry products, cobots ensure accurate and repeatable filling to guarantee a consistent product volume. Integrated vision systems check fill levels, seal integrity and labelling in real time, helping detect errors before they reach packaging. These solutions reduce waste, improve efficiency and support hygiene requirements with clean-in-place designs. Ideal for high volume production of dairy, beverages or convenience foods.