Automation That Drives Precision in Machining and Assembly

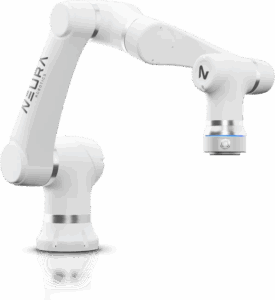

Streamlining Machining Workflows with Robotics

Metal and machining operations demand precision, repeatability and process reliability. From CNC machining and welding to part handling and assembly, modern robots are changing how metal components are produced. Robots take over repetitive, dangerous, and time-intensive tasks, ensuring high quality and consistent output. Whether for high-volume production or flexible small-batch setups, robotic systems keep machines running and skilled teams focused on complex tasks. Easy to integrate, safe in operation and adaptable to changing needs, ideal for any manufacturing environment.

Consistent Weld Quality

Automated welding with millimeter precision, even for small batches.

Uninterrupted

CNC Machining

Robots run machine tending tasks 24/7 without fatigue or errors.

Fast Changeovers for Small Series

Flexibly reprogrammable for high-mix, low-volume production environments.

Improved Workplace Safety

Working with sharp-edged parts, hot components and dangerous reworking tasks without difficulty.

Precision Welding with

Robotics

Collaborative robots are increasingly used in welding to deliver repeatable, high-quality seams, ideal for steel and aluminium components. They reduce operator exposure to heat and fumes, eliminate manual inconsistencies and handle complex welds with precision. Easily reprogrammable for different geometries and small batch sizes, cobots are perfect for shops facing skilled labor shortages. The result: improved throughput, consistent quality, and safer working environments.

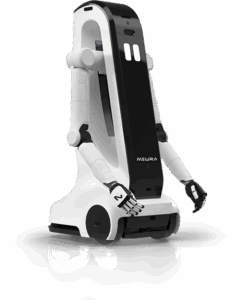

Intelligent Automation for

Multi-Shift Machine Operations

Collaborative robots are ideal for loading and unloading CNC machines, lathes and milling systems with minimal supervision. They operate safely alongside humans and can maintain production even after hours. Equipped with adaptive grippers and advanced sensors, cobots handle part variations with precision, minimizing downtime. Their fast setup and flexibility make them well-suited for mixed-product environments and frequent changeovers, ensuring optimal machine utilization and continuous output.

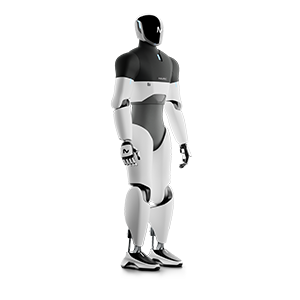

Robotic Assembly in

Metal Manufacturing

Robotic systems assist in subassembly tasks such as bolting, fitting, greasing and testing of machined parts. Collaborative robots excel in the repetition of micro-movements and can work within tight tolerances. In mixed-model production, they quickly adapt to new workflows and part types. This increases accuracy, reduces error rates, and accelerates assembly. Robots also relieve workers from repetitive, ergonomically challenging tasks, improving both productivity and working conditions.