Robotic Quality Inspection That Never Misses a Detail

Automate inspection tasks with consistent, repeatable checks built for real production - not controlled environments.

Built for High-Mix, High-Standard Environments

Quality inspection demands accuracy, consistency, and speed. But manual checks are hard to sustain and even harder to scale. Robotic inspection brings precision to every part, every shift, and every setup. Start with a standard robot using vision and force sensing or step up to built-in AI for fully adaptive inspections. Setup stays fast, results stay reliable, and your team stays focused on improving quality, not chasing it.

Automated Quality

Inspection Benefits

Consistent Results

Applies the same checks every time without variation.

Consistent Evaluation

Eliminates variation caused by human interpretation.

Faster Issue Detection

Flags problems early before defects move downstream.

Scales Across Shifts

Works continuously across shifts without slowing down.

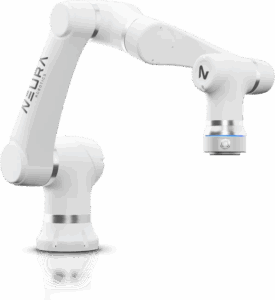

Cobot Quality Inspection

Fast, repeatable, and ready for your line.

- No-code intuitive setup

- Works with structured light, 2D or 3D cameras

- Measures distance, orientation, or alignment

- Checks parts, labels, seals, or dimensions

- Integrates with force sensing for press-fit verification

- Compact footprint for in-line or end-of-line stations

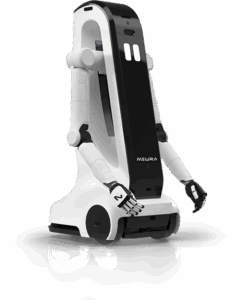

Smart Quality Inspection

Adapts to part variation, detects defects, and verifies results with no setup or add-ons.

- Detects surface defects, misalignments, and part variations with built-in AI

- Recognizes different shapes, sizes, and orientations

- Adjusts inspection paths and angles automatically

- Verifies part presence, placement, and completeness

- Flags deviations and logs results for traceability

Got any question?

Learn, connect and collaborate

What is NEURA Robotics?

NEURA Robotics is a leading robotic company powerhouse, providing end-to-end solutions covering every lifecycle of a robotic services, including setup, advisory, and so one.

Who does NEURA Robotics work with?

A detailed answer to provide information about your business, build trust with potential clients, and help convince the visitor that you are a good fit for them.

How can I partner with us?

A detailed answer to provide information about your business, build trust with potential clients, and help convince the visitor that you are a good fit for them.

Can U.S.-based clients work with NEURA?

A detailed answer to provide information about your business, build trust with potential clients, and help convince the visitor that you are a good fit for them.

What is NEURA Robotics?

NEURA Robotics is a leading robotic company powerhouse, providing end-to-end solutions covering every lifecycle of a robotic services, including setup, advisory, and so one.

Does NEURA deal with security tokens?

A detailed answer to provide information about your business, build trust with potential clients, and help convince the visitor that you are a good fit for them.

Is NEURA Robotics regulated?

A detailed answer to provide information about your business, build trust with potential clients, and help convince the visitor that you are a good fit for them.

How do I connect with NEURA Robotics?

A detailed answer to provide information about your business, build trust with potential clients, and help convince the visitor that you are a good fit for them.

See Every Detail. Deliver Every Time.

Bring speed, accuracy, and consistency to your inspection

process—without adding complexity.

Talk to an Expert